This article is a backup copy of the wikiGullet Sous vide page which is not displayed any more.

Sous vide (pronounced /suːˈviːd/) is a cooking technique where food is sealed in vacuum bags and then cooked in a controlled-temperature water bath

(Temperatures should always be given in °C and °F. For convenience here is a Fahrenheit_-_Celsius_Conversion_Table).

Principles

Sous vide has become the name of a precise cooking method involving the use of heated water baths to cook food in a carefully controlled anaerobic (air-free) environment. The method typically involves the following steps:

- Preparing the food for cooking by seasoning, brining, or marinating it;

- Sealing the food in a waterproof plastic bag from which all air has been removed;

- Heating the food to a desired core temperature, either in water at that temperature or slightly above that temperature, and holding it at that temperature for short or long periods of time

- Removing the food and any released liquid from the bag; and, as desired,

- Finishing preparation of both by searing, making a sauce, and so on.

Following step three above, food can be chilled quickly in an ice bath in order to lower the core temperature sufficiently for safe storage. SV cooking is a technique with many other applications, including infusing foods with liquids or liquids with flavors, making custards or stock, and more.

Though it is just one of many cooking techniques available, SV is relatively new to restaurant cooking and very new to home cooking. As a result, many of the techniques are still being developed and refined. In addition, the precise nature of SV cooking requires careful calculation of not only familiar variables such as cooking time and temperature but also others involving thickness and core temperature that are less familiar to many cooks. Finally, due to the anaerobic conditions inside the bag and the low temperatures used, food safety issues are paramount.

Food safety and spoilage

In addition to usual kitchen hygiene, in sous vide cooking three more aspects have to be taken into account:

- Cooking at low temperatures does not kill pathogenic organisms or spoilage organisms.

- Pasteurizing at temperatures as low as 55°C/131°F will not kill all spoilage organisms.

- Vacuum sealing food creates an (at least partially) anaerobic environment allowing growth of and toxin production by e.g. clostridium perfringens and clostridium botulinum.

At temperatures used in cooking many plant products sous vide, i.e. at 80-90°C (176-194°F), pathogenic and spoilage organisms (except spores) are killed.

At temperatures used in cooking fish and tender meat rare to medium-rare (42-54°C / 108-129°F), pathogens are not killed and thus the time the product is outside of refrigeration should be minimized. In general when cooking at these low temperatures the product is served as soon as the desired core temperature is reached, and it is strongly recommended that the bath temperature be set 1°C/2°F above the desired core temperature to speed cooking.[1]

Poultry must always be cooked to pasteurizing conditions according to Douglas Baldwin’s table 4.1. If the sous vide system is not calibrated, either temperature or time should be augmented for safe pasteurization.

Long-time low-temperature cooking to tenderize tough meat should not be done below 54.4°C/130°F with a NIST or ISO calibrated system and not below 55°C/131°F with an uncalibrated system to comply with pasteurization conditions. Note that pasteurization conditions do not inactivate all spoilage organisms which may survive at higher temperatures. Pasteurized food may nevertheless be spoiled.

Equipment and techniques

Sous vide cooking is precision cooking at controlled temperatures. Thus the one most essential and indispensable piece of equipment is an accurate thermometer to control water bath temperature.

Vacuum machines and packaging

Food has to be separated from the water of the precision water bath. For liquid food this can be a solid container (pot). For solid food, it has to be a flexible containment, i.e. a plastic bag from which all air must be removed to avoid thermal insulation by air cushions (heat conduction in water is about ten times faster than in air). Air can be removed by immersing a bag in water to displace the air and closing with a sealing rod or with a ziploc. Alternatively and preferably, bags can be vacuum-sealed using either a clamp-type vacuum sealer or a chamber vacuum machine.

Clamp type vacuum sealers

These are the usual home vacuum sealers (FoodSaver and the like). They achieve a vacuum of about 80% (some more expensive ones up to 90%) which is more than sufficient for sous vide cooking. Sealing food which is not completely dry, e.g. marinated meat or fish with olive oil and lemon juice, may be difficult and tricky, but it is possible as described in an eGullet post by PedroG, provided the machine has an instant-seal-button and a side-port; this trick will not work with fully automated machines. Clamp type machines need special bags with a texture on the inside layer allowing air to be sucked across the sealing device.

Chamber vacuum sealers

These are professional vacuum machines. They achieve vacuum levels of about 99.9% which may be useful for some special purposes like vacuum compression and vacuum infusion, but which may dramatically and negatively alter the texture of proteins, especially fish and poultry, according to experiments by Dave Arnold of the French Culinary Institute. However Dave Arnold's findings could not be verified by eGullet members; see the discussion in the Sous Vide topic in the eGullet Forums (post #376 of 29 April 2011 - 11:20 AM to post #417 of 07 May 2011 - 02:06 AM. In view of these experiments, it may be prudent to use 99% vacuum (corresponding to a boiling point of 7.1°C) with food cooled to 4°C, thus avoiding eventual damage by boiling but removing sufficient air to avoid floating of the bags.

Vacuum sealing food with liquids is easy with these machines.

Water baths and PID tuning

Cooking sous vide necessitates a constant temperature water bath. Heat transmission from the surrounding medium is about ten times faster and more reproducible in water than in air.

Temperature accuracy and stability

A 1°C difference in temperature can make a difference in organoleptic outcome. A 0.5°C difference can make a significant difference in pasteurizing times. This implicates that temperature stability should be ±0.5°C or better for simple sous vide cooking (bringing food to temperature), and the sum of accuracy and stability should be ±0.25°C or better for long-time cooking and pasteurizing. This implicates using a reference thermometer of the required accuracy.

Unheated water baths

Short-time sous vide cooking may be achieved in a kitchen sink or beverage cooler filled with hot tap water of the appropriate temperature, eventually adding some hot water every few minutes.

Simple heated water baths

With some patience and baby-sitting, a large pot on a stove-top may be kept at the desired temperature. Better stability (±0.2°C) may be achieved with a large pot (7 liters up) in a convection oven, as described in a post in the eGullet Forums.

All-in-one controlled water baths

SVS, Julabo etc.

PID controlled self-heating cookers

SVM / Auber with rice-cookers, slow-cookers, electric stock-pots, Weck....

PID controlled immersion heaters

DIY bucket heater / PID-controller / circulation pump, SVM/FMM, SWID, SVP, laboratory IC.

Electrical safety

Should the electrical insulation of a sous vide water bath fail, there would be serious danger of electrocution.

A fuse or circuit breaker does not protect a person from electrical shock, it protects the house from an electrical fire in case of a short circuit.

To protect people from electrical shock, a ground fault circuit interrupter (GFCI) is necessary.

Most GFCIs do not resume after a power failure, so even a power failure of a second would switch the sous vide water bath off. A GFCI which resumes after power failure is preferable. In a moist environment a 10mA GFCI may be tripped, a 30mA GFCI is a better choice in this case.

Thermometers and their calibration

The importance of thermometer calibration

When cooking tough meat for enzymatic tenderization at 55°C/131°F for periods longer than 4 hours one is navigating between the Scylla of safety (min. 54.4°C/130°F to prevent bacterial growth and toxin production) and the Charybdis of overdoneness. A 0.5°C deviation of water bath temperature may change pasteurization times by 20%, see the article "Importance of temperature control on pasteurizing times". Thermometer inaccuracy plus waterbath temperature oscillation ideally should not add to more than ±0.25°C. When cooking below 54.4°C/130°F temperature accuracy is less important as this means cooking in the "danger zone" anyway.

Methods of thermometer calibration

The easiest and safest way to calibrate a sous vide water bath is using a high precision reference thermometer calibrated to NIST or ISO standards and calibrating the water bath at the crucial temperature of 55°C/131°F, placing the reference thermometer probe adjacent to the water bath controller's probe and allowing the bath to stabilize at 55°C/131°C. Temperature changes during calibration have to be avoided as different thermometer probes may have different thermal time constants. See also the necessarily incomplete market overview of reference thermometers.

A somewhat less reliable method is calibration at 100°F/37.8°C with a basal thermometer.

Another possibility would be calibration against a change of a substance that happens at a sharply defined temperature, like the freezing and boiling points of water, or the color change of a thermochrome; e.g. Bis(diethylammonium)tetrachlorocuprate reversibly changes from green to yellow at 52-53°C. Unfortunately, TLC (thermochromic liquid crystal) thermometers are of poor accuracy. Extrapolation from 0°C or 100°C to 55°C may be unreliable, as neither correct slope nor linearity are guaranteed, see the Wikia article on thermometer calibration.

More than one egg will be needed with Pierre de Serres' "poorman thermometer" (cited by Frank Hsu of FreshMealsSolutions):

Stabilize water bath at 59°C/138°C; discard the yolk of one egg, and place the white in a clear sandwich bag. Put the bag in the water bath. Within minutes the egg white will show:

- As clear as raw egg white which means 135°F/57.2°C or lower

- The thin white is milky and the thick white is clear which means 137°F/58.3C

- The thin white is coagulated and the thick white is milky which means 139°F/59.4C

- Both thin and thick whites are coagulated, which means above 140°F/60°C.

The latter method requires verification, as the temperatures are not in accordance with the temperatures in the egg cooking section.

Cooking Techniques, Temperatures and Times

There are two main techniques:

- Water bath temperature is equal to the final core temperature: minimal time to reach core temperature depends on thickness of the food item, but the food can be kept in the water bath for a longer time without substantial further change of texture and doneness; pasteurizing times depend on water bath temperature and food thickness. This is the typical sous vide cooking method, which is also used in Long time cooking to tenderize tough meat.

- Water bath temperature is above final core temperature (ΔT-cooking): cooking times depend on thickness and on the difference of water bath temperature and desired core temperature, and there will be a temperature gradient in the food which will equalize to some extent after removal from the water bath. This cooking method is usually reserved for special purposes like e.g. "the perfect egg".

Measuring thickness of food items

Thickness determines minimal cooking times and pasteurizing times. Measuring thickness may be facilitated by a thickness ruler which can be downloaded from the eGullet forums.

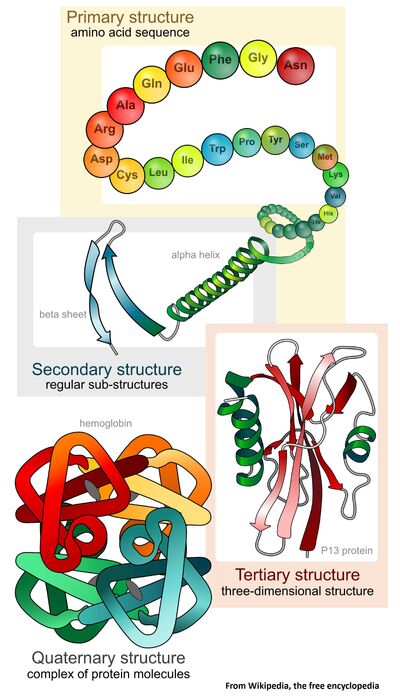

The structure and denaturation of Proteins

The amino acid sequence of proteins determines how the protein will spontaneously fold to form its secondary structure (α-helices and β-sheets) and tertiary structure (three-dimensional arrangement of α-helices and β-sheets) and even its quaternary structure. At higher temperatures, proteins are denatured, i.e. they lose their quaternary and tertiary structure and to some extent even their secondary structure (uncoiling). In some proteins, the process of denaturation is reversible, in others it is irreversible, as is the case in the proteins involved in egg cookery (see section 4.2), where uncoiled proteins form cross links, resulting in a three-dimensional meshwork (imagine like a 3D cobweb) , which encloses the remaining liquid components of the egg, resulting in higher viscosity. This may explain why denaturation of only 10% of the proteins in the egg yolk can increase viscosity to such an extent.

A reversible process will come to equilibrium, whereas an irreversible process will reach an end point; this happens slowly at lower temperatures and faster at higher temperatures. Temperature is the average energy level of the molecules of a substance. To undergo a reaction process, the individual molecule must have a minimal energy level, called threshold. At low temperatures, very few molecules at a time have the threshold energy level to undergo the reaction, so the reaction eventually proceeds so slowly as to go unnoticed in an experimental setting with a limited time frame. At a temperature that equals the threshold, half the molecules can undergo the reaction simultaneously, so the reaction will be very fast. At an even higher temperature with most of the molecules being above threshold temperature, the reaction will happen immediately. This explains why not only temperature but also time play a role in achieving the desired effect on food; this is most important in achieving a desired viscosity of an egg yolk or an egg white (see section 4.2), and in tenderizing meat.

Proteins can be divided into structural proteins (e.g. myofibrillar proteins and connective tissue proteins) and functional proteins (e.g. enzymes, hormones, antibodies, storage proteins, transport proteins). An important aspect of cooking is denaturation of structural proteins, which can be achieved among others by enzyme action, elevating temperature, changing pH (acids like vinegar, mustard, lemon juice, bases like baking soda) or salt concentration. Enzymes help in tenderizing (aging) meat, especially calpains and cathepsins are involved in aging meat by weakening supporting proteins and contracting filaments and breaking cross-links between collagen fibers, allowing collagenases to hydrolyse collagen into gelatin. Calpains become denatured and inactivated around 40°C/105°F, the same is true for cathepsins around 50°C/122°C and for collagenases around 60°C/140°F. So keeping meat slightly below 40°C for a few hours may help in tenderizing muscle fibers and in preventing shrinkage of the collagen sheaths that surround muscle fibers, which would squeeze juices out of muscle fibers on further heating.[2]

Cooking tender proteins

Tender proteins are proteins low in connective tissue, e.g. fish, most poultry, tender cuts of meat (beef, veal, pork, lamb etc.).

Fish

Fish of a quality allowing it to be eaten raw may be cooked to a rare to medium-rare doneness at the transition from translucent to opaque, i.e. to a core temperature around 45°C/110°F[3]. As parasites like Anisakis worms survive this temperature, it is recommended to freeze fish before use at -20°C/-4°F for 24h (European Union) to 7 days (U.S. FDA)[4]. When serving immune compromised persons, fish should be pasteurized according to Douglas Baldwin's Practical Guide, preferably at 60.5°C to avoid prolonged cooking times which might produce a mushy texture (see a post in eGullet forums by Douglas Baldwin. When vacuum-sealing fish, medium vacuums (i.e. 99% up) as produced by chamber vacuum machines should be avoided, because vacuum over 90% may result in a mushy texture of fish, as has been experimentally shown by Dave Arnold of the French Culinary Institute. Clamp type machines are ok, ziploc bags will do as well, especially when adding liquids like lemon juice and olive oil.

Poultry

Chicken and other poultry like turkey breasts should always be cooked to pasteurizing conditions according to Douglas Baldwin's Practical Guide. Most recommended temperatures are 63,5°C/146°F where pasteurizing times are almost equal to heating times, or 60.5°C/141°F with slightly longer pasteurizing times. Vacuum levels above 90% should be avoided, they might compromise the texture of poultry [1].

Meat

Tender cuts of meat like tenderloin, sirloin and rib-eye of beef or veal, lamb chops and lamb racks, filet mignon of pork, pork neck and pork chops may be cooked to the desired doneness (49-52°C/120-126°F for rare, 53-55°C/127-131°F for medium-rare, or 60°C/140°F for medium) after vacuum-sealing either as is or with a dry rub or marinade. Beef may become more tender by aging for a few days in marinade. Cooking times are given in Douglas Baldwin's Practical Guide.

Cooking tough proteins

Tough proteins are proteins rich in connective tissue, e.g. tough cuts of meat (beef, veal, pork, lamb etc.). The main component of connective tissue is collagen which can be converted to gelatin at higher temperatures, making the meat tender and succulent. Unfortunately, collagen starts shrinking above 60°C/140°F [5], squeezing out the juices and making the meat dry long before collagen is converted to gelatin at a considerable rate at temperatures above 70°C/158°F. Fortunately, collagen is also converted to gelatin enzymatically by collagenase at temperatures below 60°C/140°F,[6] although at a slower rate. In contrast to a few hours necessary for tenderization at temperatures above 70°C/158°F, it takes a few days (24-72 hours) at temperatures below 60°C/140°F; this implicates the danger zone has to be avoided, i.e. temperature should not be below 54.4°C/130°F. Recommended temperatures for LTLT (long-time low-temperature) cooking are 55°C/131°F to 57°C/135°F to achieve fork-tender succulent medium-rare meat. If a doneness comparable to traditional braising is desired, water bath temperature may be raised to 78°C/172°F for a few hours after enzymatic tenderization, thus avoiding dehydration by collagen shrinking above 60°C/140°F as collagen has already been enzymatically converted to gelatin below 60°C/140°F. Temperatures above 80°C/176°F should be avoided as actin gets denatured[7], making meat hard like shoe-leather Template:Citation needed.

Cooking eggs

Cooking eggs in the shell is not strictly sous vide cooking, but a temperature-controlled water-bath as used in sous vide cooking is a practical tool for cooking eggs.

Valuable information has been published at Khymos: "Towards the perfect soft boiled egg".

The important temperatures and proteins when cooking an egg are[8]:

- 143°F (61.5°C): the protein conalbumin (aka ovotransferrin, about 12-13% of the egg white) denatures and causes the egg white to form a loose gel

- 148°F (64.5°C): the proteins α-livetin and γ-livetin (about 10% of the egg yolk) denature and cause the egg yolk to form a tender gel

- 158°F (70°C): the protein ovomucoid (11% of the egg white) denatures and causes the egg white to form a firm gel (the LDLs that make up 68% of the egg yolk also coagulate around this temperature)

- 184°F (84.5°C): the protein ovalbumin (54% of the egg white) denatures and causes the egg white to become rubbery

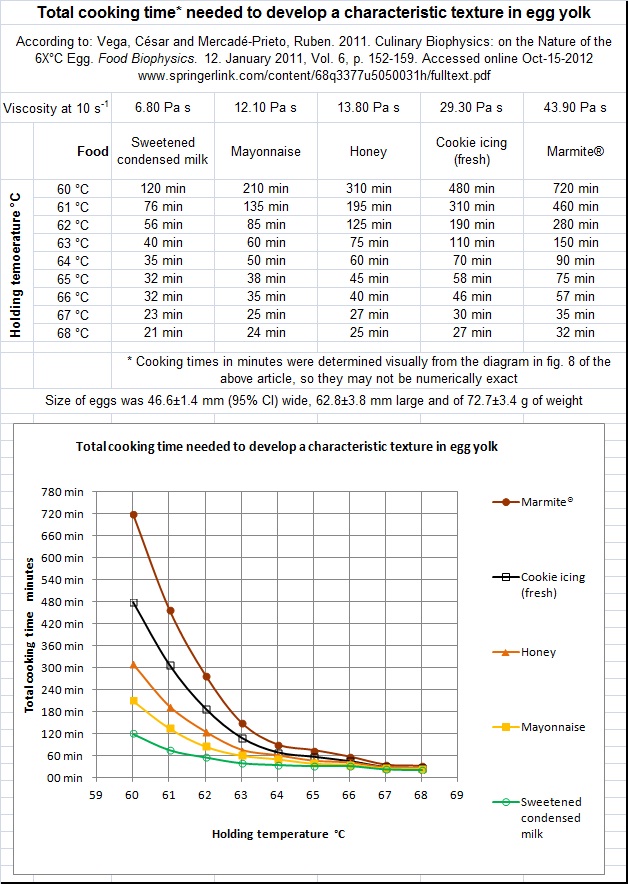

Newer research by César Vega & Ruben Mercadé-Prieto[9] showed that the proteins responsible for gelation of the egg yolk below 75°C are α-livetin and γ-livetin (which begin to be denatured at 60°C) and LDL (low density lipoproteins) which begin to be denatured at 70°C, and that heat transport across the egg white is faster than pure heat conduction would explain, as heat convection plays an important role as long as the egg white is not yet coagulated, as is the case in 6X°C eggs, whereas while cooking eggs in boiling water, the egg white is coagulated rapidly, thus inhibiting convection and making heat transport slower. Furthermore they found that viscosity of egg yolks kept at a constant temperature increases with time. To understand why this is the case, have a look at the section “The structure and denaturation of proteins”.

The Onsen tamago or 6X°C egg

Onsen means hot spring, tamago is egg in Japanese. Hot spring temperatures range from body temperature to 74°C (hottest spring in continental Europe in Aachen) to 97 °C (Deildartunguhver hotspring in Reykholtsdalur, Iceland). Controlled temperature water baths as used in sous vide cooking make it possible to cook onsen eggs at home. They are also called reverse cooked eggs, as the yolk is harder than the egg white.

César Vega & Ruben Mercadé-Prieto [10] published a diagram that allows selecting a time-temperature-combination to achieve the desired result. E.g. an onsen egg with a yolk of mayonnaise-like viscosity will be achieved at 60°C / 210 min, 61°C / 130 min or 64°C / 50 min respectively; the egg white will remain runny and is usually discarded. Note that viscosity in kg/(s•m) has been translated into understandable mouth feel terms like “mayonnaise”, “honey” etc.

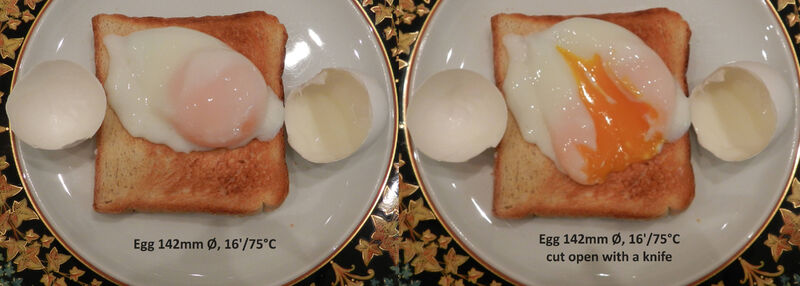

The perfect poached egg

Cooking eggs in boiling water for a time to achieve a creamy yolk will inevitably overcook the outer portions of the egg white, making it rubbery. To achieve a soft yolk and a soft gelled white, cooking temperatures between 70°C and 84.5°C should be used, so conalbumin and ovomucoid (but not ovalbumin) will be denatured.

The table "In-Shell Egg Heating Times in a 75°C Water Bath Using Circumference or Diameter for Chicken Eggs, starting from 5°C by Douglas E. Baldwin" can be downloaded from eGullet forums. Measuring circumference or diameter of eggs is facilitated by an egg ruler or a caliper.

The soft-boiled egg with a set white and a soft yolk

This may be achieved by cooking an onsen egg to the desired yolk viscosity, chilling to room temperature and boiling for 2 or 3 minutes to set the white. Practically the same result can be achieved with a traditional egg cooker in a few minutes.

Scrambled Eggs

Mix eggs (100%) together with no more than 25% liquid (milk or half-and-half or cream), spice to taste with salt and pepper, vacuum seal or place in a Ziploc bag, place in a 72°C water bath for 25 minutes. This yields soft scrambled eggs with a uniform soft texture. If a mixture of lumps and soft eggs is desired, cook traditionally in a skillet.

Pasteurized in Shell Egg

While only 1 in 10,000–20,000 intact shell eggs contain hazardous levels of Salmonella enteritidis (McGee, 2004[11]; Snyder, 2006 [12]), Grade A eggs were implicated in 82% of outbreaks between 1985 and 1991 (Mishu et al., 1994[13]). Therefore, when working with highly susceptible or immune compromised populations, pasteurized eggs should always be used in dishes which call for raw eggs (e.g., chocolate mousses). Place egg in a 135°F (57°C) water bath for at least 1 hour and 15 minutes (Schuman et al., 1997[14]). Pasteurized intact eggs can be stored and used just like raw eggs. While the properties of the egg yolk are unaffected, the egg white is milky compared to a raw egg. Whipping time is significantly longer for pasteurized eggs, but the final whip volume is nearly the same (Schuman et al., 1997).

Practical Hints

Cracked eggs and avoiding messed up SV rig

Expansion of the air bubble is not the reason that makes eggs crack.[15] Air is a poor heat conductor and will heat and expand slowly, increasing pressure slowly by about 25% while heating from 5°C (278K) to 75°C (348K). Cracks happen shortly after immersing the egg in hot water, not at the end of the cooking time. Egg shells may sometimes have uneven thickness, so the thinner parts will heat and expand faster than the thicker ones, leading to tension cracks. Pricking the blunt end of the egg may lead to microscopic relaxing cracks thus avoiding macroscopic tension cracks. Another reason for cracking may be bumping against the bottom of the cooking container.

Cleaning a sous vide rig that has been messed up by a cracked egg may be very tedious, especially in immersion circulators or sous vide baths circulated by an indoor fountain pump. A professional grill-cleaning-solution containing sodium hydroxide (e.g. Johnson Diversey D9 SUMA Grill heavy duty oven cleaner) may help.

To avoid a mess by cracked eggs, it is recommended to place the eggs in a Ziploc bag, submerging the bag in the preheated sous vide water bath to fill it with sufficient water to displace the air around the eggs, and suspending the bag (e.g. with a skewer) to avoid bumping and to facilitate rapid retrieval.

Cooking vegetables and fruits

Green vegetables may be blanched in sous vide bags in boiling water. This improves the flavor over traditional blanching by preventing water-soluble flavor compounds from leeching into the cooking water.

For vegetables where chlorophyll discoloration is not a concern, such as root vegetables, cooking at 85°C/185°F is commonly recommended.

Literal Translation of "sous vide"

The French phrase "Sous vide" translates literally as "under vacuum," referring to the vacuum that is used to remove air from the bags used to contain food in a water bath. However, the phrase "sous vide" (or SV for short) is often taken to mean "under pressure," Template:Citation needed which is a misnomer: SV cooking neither involves cooking "under pressure" meaning above atmospheric pressure (e.g. in an autoclave) nor cooking at "under-pressure" meaning under a vacuum, i.e. at a pressure below atmospheric pressure. No matter how strong a vacuum was applied to remove the air, pressure in a plastic bag is always equal to atmospheric pressure provided the bag is not inflated by expanding gas.

Literature

Books

Online publications

eG Forums discussions and index

Chris Amirault has indexed the original eG Forums Sous Vide topic: that index may be found here. For the latest sous vide discussion, see the current eG Forums Sous Vide topic here.

References

- ↑ Template:CiteMC

- ↑ Template:CiteMcGee

- ↑ Template:CiteMcGee

- ↑ http://en.wikipedia.org/wiki/Sashimi#Safety_notes Wikipedia, Sashimi, Safety notes

- ↑ Template:CiteMcGee

- ↑ http://www.douglasbaldwin.com/sous-vide.html#Tough_Meat Douglas Baldwin A Practical Guide to Sous Vide Cooking, Chapter 2 “Basic Technique, Cooking, Tough Meat”

- ↑ Template:CiteMcGee

- ↑ http://egullet.org/p1778321 scientific background of egg cooking by Douglas Baldwin

- ↑ Vega, César and Mercadé-Prieto, Ruben. 2011. Culinary Biophysics: on the Nature of the 6X°C Egg. Food Biophysics. 12. January 2011, Bd. 6, S. 152-159. Accessed online Oct-15-2012 www.springerlink.com/content/68q3377u5050031h/fulltext.pdf

- ↑ Vega, César and Mercadé-Prieto, Ruben. 2011. Culinary Biophysics: on the Nature of the 6X°C Egg. Food Biophysics. 12. January 2011, Bd. 6, S. 152-159. Accessed online Oct-15-2012 www.springerlink.com/content/68q3377u5050031h/fulltext.pdf

- ↑ Template:CiteMcGee

- ↑ Snyder O.P., Hospitality Institute of Technology and Management: FOOD SAFETY HAZARDS AND CONTROLS FOR THE HOME FOOD PREPARER http://www.hi-tm.com/homeprep/Home-2006-2col-forpdf.pdf

- ↑ Mishu B. et al., Outbreaks of Salmonella enteritidis Infections in the United States, 1985-1991 http://jid.oxfordjournals.org/content/169/3/547.short

- ↑ Schuman et al., Journal of Applied Microbiology 1997, 83, 438–444: Immersion heat treatments for inactivation of Salmonella enteritidis with intact eggs http://onlinelibrary.wiley.com/doi/10.1046/j.1365-2672.1997.00253.x/pdf

- ↑ Gruber, Werner. 2008. Die Genussformel, Kulinarische Physik. Salzburg : Ecowin Verlag GmbH, 2008. p. 80-82